Which bushings are best for my dedicated race car?

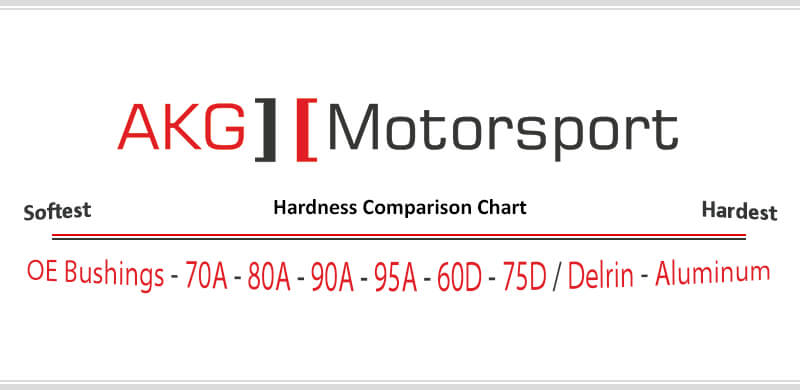

We provide both hard durometer polyurethane and aluminum bushings for race cars. For those who wish to use polyurethane, we offer a 75D hardness. 75D is by far the hardest polyurethane compound available on the market for a BMW and will tremendously improve many aspects of a race car’s handling characteristics. Our 75D polyurethane bushings utilize the correct compound polyurethane required to control a racecar’s suspension geometry during the rapid movements a race car experiences on the track.

For those who want to go a step further, we also offer aluminum bushings for most models. Remember: unlike even the hardest polyurethane, aluminum is extremely harsh on the chassis. When using aluminum bushings and mounts, it is necessary to be sure the car is well-reinforced, and inspected consistently before and after each race. For this reason, aluminum bushings are only recommended for dedicated track cars.

Which bushings are best for my high performance street car?

High performance street cars will see a noticeable increase in performance with our medium durometer bushings. These would include 80A, 85A, 90A and 95A durometers. These bushings utilize the most ideal hardness and compound for street/performance use, providing for an increase in performance without a large increase in NVH (Noise/Vibration/Harshness).

Why don’t you use nylon or Delrin in your motor mounts or suspension bushings?

Polyurethane is an elastomer in the rubber family; it is not a plastic. We specifically exclude the use of plastics and nylons in all of our motor mounts and suspension bushings. Through our research and testing, we’ve come to the conclusion that plastic (including Delrin and UHMW) and nylon are not suitable for use in either of these locations, due to these materials’ lack of memory. By this, we mean that if plastic or nylon is compressed, it does not return to its original size; polyurethane does have this memory. Also, plastics and nylons have a shorter life expectancy than any urethane, especially the hardest compound polyurethanes. We also exclude the use of Delrin in our mounts and suspension bushings due to its brittleness. Poly 75D has virtually the same hardness as Delrin, but is not a brittle material.

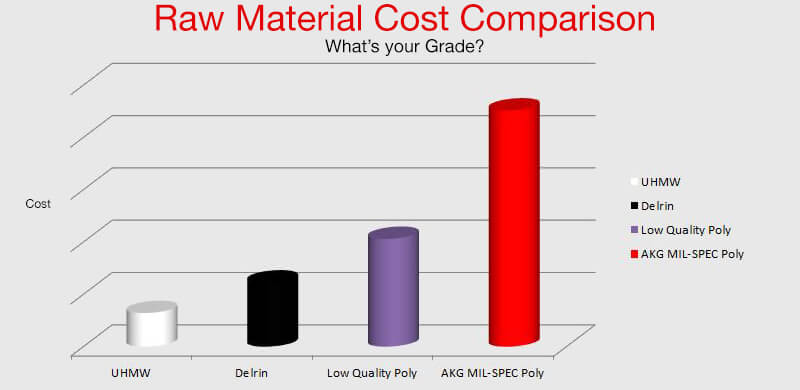

Raw Materials Cost Comparison

We’re proud to offer high-quality, US Military Spec polyurethane performance parts, made entirely in the USA under strict ISO 9001:2015 certified processes. What’s even more amazing is that our products are competitively priced compared to other much cheaper alternatives (low-grade poly, Delrin and UHMW), even though the raw-materials cost of our proprietary US Military Spec polyurethane is over 4 times the price of Delrin and over 7 times the price of UHMW!