Designed to Out-Perform. And They Do.

AKG Motorsport performance mounts for BMW are used all over the world, from daily-driven street cars to high-performance race cars – and for good reason. All of our motor and transmission mounts are designed to be the best performing and most reliable mounts available for your BMW. A feat achieved through truly innovative designs, the highest-quality materials and an unrivaled manufacturing process – for performance mounts that out-perform and out-last everything else.

Innovative Design. Refined.

Our molds encompass two generations, designed and built right here in Illinois. The first generation mold is developed to test and further refine our design for the final production mold. This process gives us complete control over our designs, tolerances, and fitments, and is the first step in manufacturing a high-quality, precision molded performance bushing for your BMW.

Quality You Can See. And Feel.

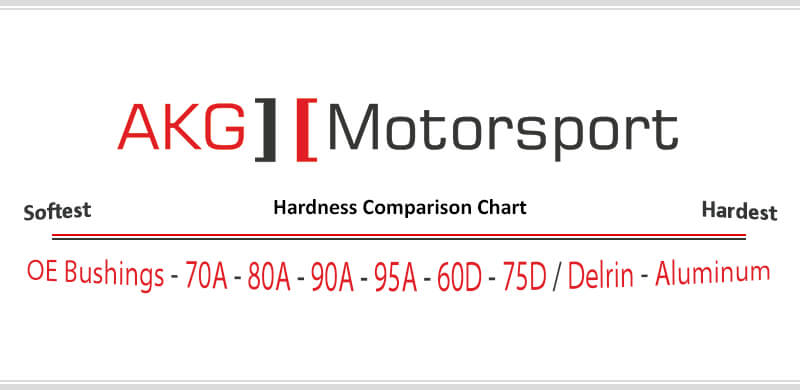

Each mount is made of the highest quality US Military Spec polyurethane available, which is supplied to us through ISO 9001:2015 certified suppliers. The compounds and durometers we use are chosen based upon both the design and its intended use, and range from medium 70A-95A street performance compounds to our rock hard, race-proven 75D compound. The quality of our performance mounts is so far ahead of anything else available, that you can actually see and feel the difference yourself.

75D is by far the hardest polyurethane compound available on the market for a BMW, but unlike solid aluminum mounts, are not harsh on the chassis. AKG 75D mounts utilize the correct compound polyurethane required to sufficiently control a race car’s drivetrain as torque moves through to the rear wheels. For those who want to go a step further, precision CNC crafted aluminum mounts are available for most models.

ISO 9001:2015 Certified Molding. For Unrivaled Quality.

The polyurethane in our mounts is formed with our precision molds through a meticulous ISO 9001:2015 certified process which provides the quality, durability and consistent reliability our performance parts are known for. There are many important steps in our operations including hardness and dimension checks, constant machine calibrations and a continuous, stringent analysis of raw materials. All of which play an important role in ensuring a quality performance part.

In fact, our process easily handles 75D – a notoriously difficult durometer to not just mold correctly, but consistently – a testament to our unrivaled quality. Watch the video to learn more.

Design. Meets Function.

Our mounts are uniquely refined and incorporate many firsts in design. These features have the sole purpose of improving the overall performance of our mounts. CAD/CAM design, in-house mold design, the highest quality materials and our expert knowledge of these cars provides for mounts that are unparalleled by any measure.

Firsts In Design. It’s What We Do.

Built for racing, our performance mounts are the first and only fully re-buildable, bolt-through designs capable of withstanding the high loads experienced in everything from road racing cars to rally cars to 700RWHP drag cars. So go ahead – show that pedal who’s boss.

From I6’s, to V8’s to V12’s – we’ve been engine swapping BMW’s since the 80’s. The first S50/M50 to E30 swap mounts were designed by us and to this day are the only mounts with the proper angle and stud location – because your swap deserves a perfect fit.

AKG Group N motor mounts feature an exclusive interlocking system within the mount, making them much stiffer without compromising comfort. This design also does not allow for separation of the motor mount. Your engine bay will thank us.